-40%

Heavy Duty 40 Series Torque Converter Back Plate Comet Clone TAV Backplate

$ 88.7

- Description

- Size Guide

Description

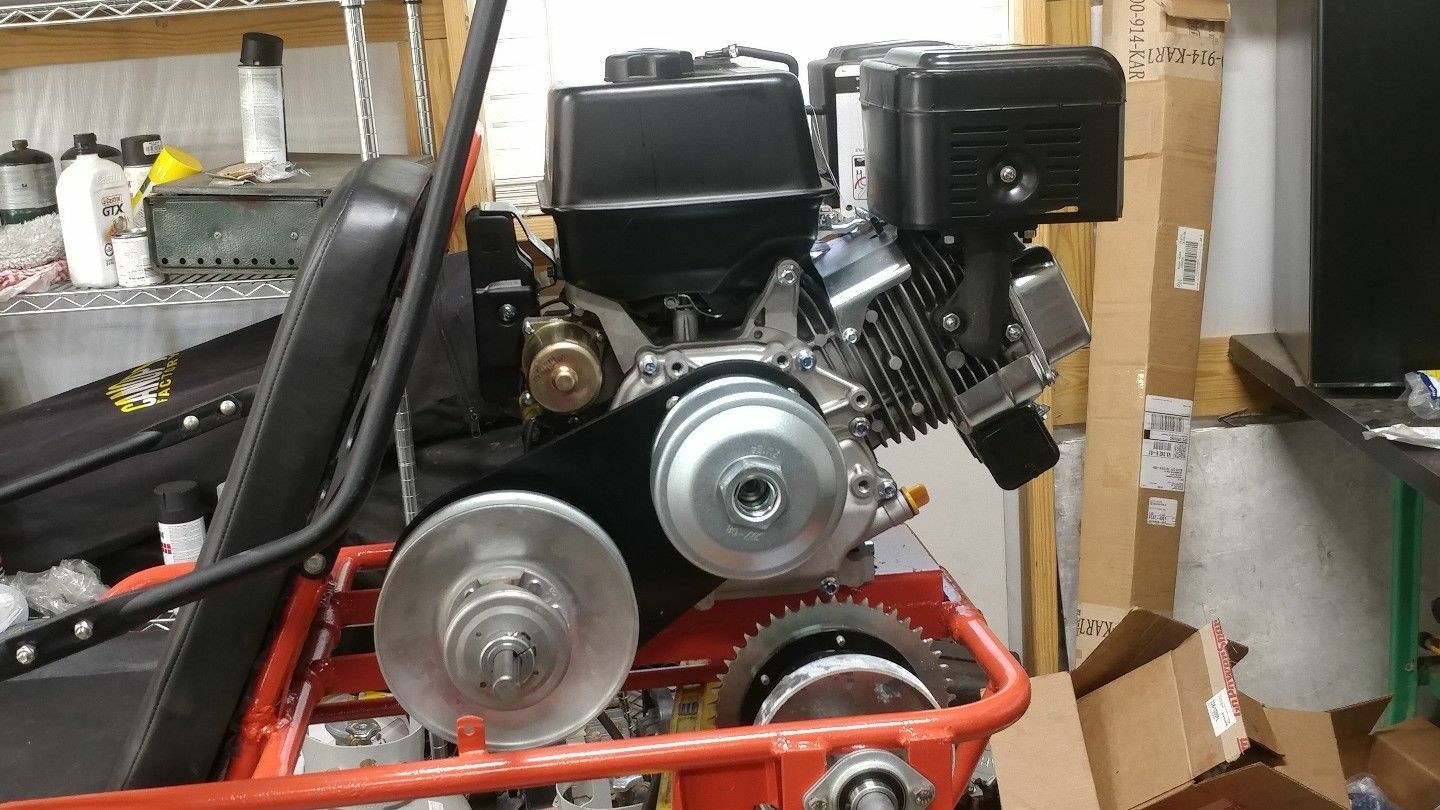

Just released! The second generation of our popular plate is now pre-drilled with a double 360 degree pattern for GX120 through GX390 and Vanguard V-twin mounting patterns! Mock up pictures in ad are with genuine Honda GX390 engines.Best built plate available, 1/4” thick solid steel plate with welded gussets, made in Michigan!!!

Heavy duty 40 series torque converter back plate, the hardest part of the kit to find. This is not a complete kit, does not include pulleys or belt. This plate is water jet cut from 1/4" thick solid plate steel and has 3 gussets welded to support the bearing tube, not a thin stamped piece of galvanized tin that flexes and bends or a bearing tube that bolts on. If you have a big block engine, and plan to make serious power or run heavy loads such as soft sand or hard acceleration, this plate will not deflect, we use it on modified 18hp Vanguard V-twin engines in racing minibikes making 30hp-40hp range. When used with a Kevlar belt, this is a bulletproof setup. Great for use on high performance engines with a 1" crank diameter, Predator 420's, GX270/290/340/390, Vanguard V-Twins, etc.... Great setup for high output GX200's that are destroying TAV2 30 series belts and shafts. Here is a brief video of our plate in use sent to me from a very happy customer with GX390 power:

https://youtu.be/Yr5gx0K6iG4

This is a custom fabrication piece which will typically be bolt on. In some fitment cases you may or may not need slight modification to fit, such as using washers behind the plate to move it out slightly, trimming the plate, trimming cylinder or head fins, trimming one of the gussets, oblonging mounting holes to index to your exact desire, depending upon how and where you want the plate to angle, your exhaust, etc.....

This auction ad is for one pre-drilled single 40 series back plate with bearings, shaft, locking collets, and bearing support tube (already welded in) with gussets. This auction is for the plate and shaft setup only, does not include the belt, sprocket, or either pulley. It does include 12" of 3/4" keyed shaft, 2 locking collets, and a section of key stock. This is about 2" additional shaft length over what is typically needed to install a sprocket and driven unit, to give you some flexibility. The extra shaft length gives you a chance to mount a disc brake if you are unable to on your axle.

This is a fantastic system for medium and big block engines such as Honda GX240, GX270, GX340, GX390, Harbor Freight Predator 420 engines, as well as V-twin Vanguard, and others. If you want your kart to pull wheelies and still exceed 70mph, this is the way to get there, as seen on YouTube. The variable ratio gives almost 3:1 on take off, and up to 1:1 at speed, depending on which driven unit you go with. 40 series system components can be specifically tuned to your liking on engagement RPM's and upshifting speeds.

We have listened and are now shipping this engine mountable torque converter backplate for the Comet and clone 40 series torque converters. The 40 series torque converter is typically separate units, but this plate will allow you to plug and play the entire system directly onto an engine, exactly like the 30 series currently does. This makes mounting, correct belt length, and chain adjustment much simpler, in nearly any application. Many potential customers have expressed interest in acquiring the backplate only. We are delivering exactly this, for the ultimate low-buck DIY setup.

Our plate is very heavy 1/4" steel, and includes a 12" long 3/4" diameter keyed shaft for the driven unit and high speed sealed bearings. The bearings we use are USA made precision ground and rated beyond 5,000rpm continuous speed. Pulley center-center distance is 8-3/16". This center distance was chosen as it is the shortest one which fits both the GX390 and Briggs Vanguard V-Twin engines, and also allows you to use any combination choices of 40/44 driver and driven units. With the drive pulley, these are available for 3/4", 1", and 1-1/8" engine shaft diameters. For the driven pulley, there are 2 choices of diameter on the market (7.5" 40D and 8.5" 44D), so you can select either to optimize your drive ratio range. Ratio ranges are 1.1 - 2.43 with 7.5" 40D, and 1.24 - 2.83 with 8.5" 44D. Be sure to get the driven pulley you want in 3/4" bore diameter. We are manufacturing and selling the backplate only with bearings and support tube already welded in, as you can purchase the 40 series pulleys, sprocket, and belt for very low cost elsewhere on the internet.

Our design allows you to assemble your kit via the lowest cost possible and with the most flexibility. You source both pulleys, belt, and your own drive sprocket. Drive sprocket and driven pulley needs to be for 3/4" keyed shaft, which are readily available in nearly all chain size and number of teeth. Tailor it to your exact needs. The included 3/4" driven shaft is extra long, which you cut down to size once you have installed your sprocket and driven pulley. Two 3/4" single bolt shaft collars are included to make assembly very easy, one will already be installed. Install your sprocket on the shaft up against the plate, sandwiched between the plate and driven pulley, same as the 30 series TAV2 does.

If you have a Vanguard twin, you can easily remove the oil filter adapter and install the Briggs filter delete plate kit, as we did on the Vanguard V-Twin pictured. Briggs part number 807689 is the oil filter block plate to do this.

This is a single key component of a total system. It has been designed to allow as much flexibility as possible in your configuration. Remaining assembly is as simple as drilling and bolting the plate to your engine and sliding the sprocket and driven unit onto the shaft, then adding the clamp. If you desire a belt guard, you will need to fabricate one.

To recap, the following is what you will need to acquire to complete the system: 40 or 44 series driver and driven units, belt (depends which of the 2 different driven unit you are using), chain sprocket for 3/4" keyed shaft, and fabricate a belt guard if you want one. Depending upon crankshaft length, you may need to space the driver or driven unit for best belt alignment.

7.5" 40D driven pulley - use Comet belt p/n 203785A or equivalent. 8.5" 44D driven pulley, use Comet belt p/n 203787A or equivalent.

Standard hp capability of the 40 series torque converter is 8-18hp range. We have successfully used these at much higher power levels by using Kevlar belts.

On the driven unit, you will need to acquire and install a "reverse wound" yellow spring, and reassemble the driven unit pulley to ride on the opposite ramps it normally ships with. This is called "outboard mounting" and is very easy to reconfigure for. Comet "reverse wound" yellow spring p/n 204524A.

US 48 state shipping is included in the purchase price. No returns once plate has been drilled. Returns accepted on purchase price of returned unused plate, -20% restocking fee. No refund or reimbursement on any shipping.